Steel has been a cornerstone of industrial progress for centuries but it wasn't until the Bessemer process that mass production became a reality. This groundbreaking method transformed how we create steel and paved the way for modern infrastructure. Imagine a world where building skyscrapers or constructing railways took years instead of months. The Bessemer process changed all that by making steel production faster and cheaper. So let's dive in and uncover how this remarkable innovation continues to shape our world today

When you think about steel you might picture towering buildings or sleek automobiles but what you may not realize is that the journey of modern steel began in the mid-19th century. The Bessemer process steel marked a turning point in manufacturing history. Before this invention producing steel was a labor-intensive and costly affair. But with the introduction of the Bessemer process steel became accessible to industries worldwide driving economic growth and technological advancement

Now here's the kicker – the Bessemer process wasn't just about making steel cheaper. It was about revolutionizing the way we build our world. From bridges that span miles to machines that power factories this process laid the foundation for the industrial age we live in today. So whether you're an engineer history buff or simply curious about how the world works this article will take you on a fascinating journey through the history and impact of the Bessemer process steel

Read also:Anna Malygon Naked Unveiling The Truth Behind The Viral Sensation

What Exactly is the Bessemer Process Steel?

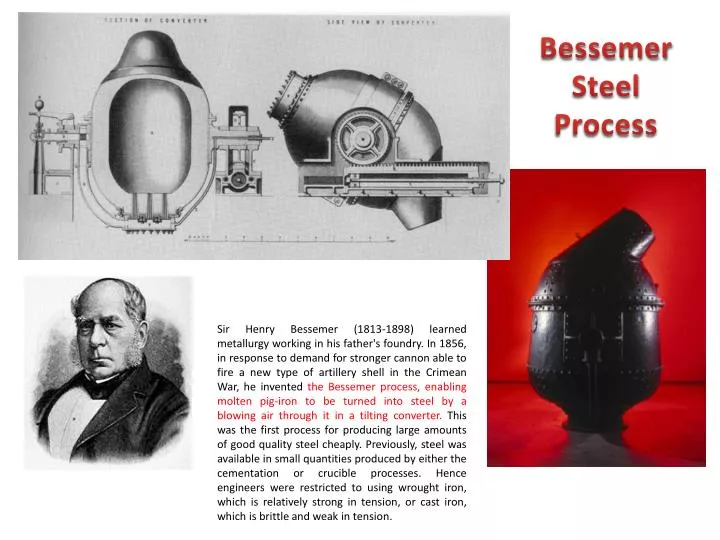

The Bessemer process steel is more than just a manufacturing technique – it's a game-changer in the world of metallurgy. Developed by Sir Henry Bessemer in the 1850s this method involves blowing air through molten iron to remove impurities and produce high-quality steel. The result? A stronger more durable material that could be mass-produced at a fraction of the cost compared to traditional methods. This breakthrough made steel accessible to industries ranging from construction to transportation

Let's break it down. Before the Bessemer process steel production relied heavily on labor-intensive techniques like puddling and cementation. These methods were not only time-consuming but also expensive making steel a luxury item. But with the introduction of the Bessemer process steel production became faster and more efficient. By removing carbon and other impurities through oxidation the process created a material that was both strong and malleable perfect for industrial use

But why does this matter? Well consider this – before the Bessemer process steel was so expensive that it was rarely used in construction. Buildings were primarily made of wood or stone limiting their size and durability. The introduction of affordable steel changed all that allowing architects and engineers to dream bigger and bolder. Suddenly skyscrapers railways and bridges became a reality transforming cities and connecting nations

Key Features of the Bessemer Process

Here are the standout features that make the Bessemer process steel so revolutionary:

- Blow-through Method: Air is blown through molten iron to remove impurities

- Mass Production: The process allows for large-scale steel production at a lower cost

- High-Quality Output: The resulting steel is stronger and more durable than previous methods

- Innovative Design: The Bessemer converter – a specialized vessel used in the process – became an icon of industrial progress

These features combined to create a process that was not only efficient but also scalable. Factories could produce steel in quantities that were unimaginable before making it accessible to industries across the globe

The History Behind the Bessemer Process Steel

To truly understand the impact of the Bessemer process steel we need to look back at its origins. In the mid-1800s the industrial world was on the brink of change. The demand for steel was growing rapidly but the methods of production were outdated and expensive. Enter Sir Henry Bessemer a British inventor who saw an opportunity to revolutionize the industry. Through years of experimentation Bessemer developed a process that would change the world forever

Read also:Maddipann Nude The Truth Behind The Viral Sensation

But it wasn't all smooth sailing. Bessemer faced skepticism and resistance from traditionalists who were reluctant to embrace new technology. However his persistence paid off and by 1856 he had successfully demonstrated the process to the public. The reaction was overwhelming as industries quickly realized the potential of this new method. Within years the Bessemer process steel became the standard for steel production worldwide

Here's a timeline of key events in the history of the Bessemer process:

- 1850s: Sir Henry Bessemer begins experimenting with air-blown methods

- 1856: The first successful demonstration of the Bessemer process

- 1860s: The process is adopted by major steel producers globally

- 1870s: The Bessemer process becomes the dominant method for steel production

As you can see the journey from invention to adoption was a testament to Bessemer's vision and determination. His work laid the foundation for modern steel production and changed the course of industrial history

How Did the Bessemer Process Change the World?

The impact of the Bessemer process steel extends far beyond the factory floor. This innovation transformed entire industries and reshaped the way we live. Think about it – without affordable steel we wouldn't have the skyscrapers that define our cities or the railways that connect them. The Bessemer process made it possible to build larger stronger structures at a fraction of the cost compared to previous methods

But the changes didn't stop there. The availability of cheap steel spurred innovation in other industries as well. Automobile manufacturers could produce cars with steel frames making them safer and more durable. Construction companies could build bridges that spanned greater distances and railways that stretched across continents. Even agriculture benefited as steel tools and machinery became more accessible

The Science Behind the Bessemer Process Steel

So how exactly does the Bessemer process work? At its core the process involves removing impurities from molten iron through oxidation. Here's a step-by-step breakdown:

- Melting: Iron is melted in a specialized vessel called a Bessemer converter

- Air Blowing: Air is blown through the molten iron causing impurities to oxidize and burn off

- Refining: The remaining material is refined to produce high-quality steel

- Casting: The final product is cast into molds for use in various applications

What makes the Bessemer process so effective is its ability to remove impurities quickly and efficiently. By blowing air through the molten iron the process creates a chemical reaction that burns off carbon and other unwanted elements. The result is a cleaner stronger material that's perfect for industrial use

Advantages of the Bessemer Process

Here are some of the key advantages that make the Bessemer process steel so appealing:

- Cost-Effective: Produces steel at a fraction of the cost compared to traditional methods

- Efficient: The process is faster and requires less labor than older techniques

- Scalable: Can be used to produce steel in large quantities making it ideal for mass production

- Innovative: Pioneered the use of air-blown methods in steel production

These advantages combined to make the Bessemer process the go-to method for steel production for decades. Even today it remains a benchmark for innovation and efficiency in the industry

Challenges and Limitations of the Bessemer Process Steel

While the Bessemer process steel revolutionized the industry it wasn't without its challenges. One of the main limitations was its inability to handle certain types of iron ore. The process required specific conditions to work effectively which limited its application in some regions. Additionally the process produced steel with a high phosphorus content which could compromise its strength and durability

Another challenge was the environmental impact. The Bessemer process involved high temperatures and large amounts of energy which contributed to air pollution. Factories using the process often faced criticism for their environmental footprint prompting the development of cleaner more sustainable methods

Modern Alternatives to the Bessemer Process

As technology advanced new methods of steel production emerged that addressed some of the limitations of the Bessemer process. One such method is the Basic Oxygen Furnace (BOF) which uses pure oxygen instead of air to remove impurities. This process produces higher-quality steel with fewer impurities and is more environmentally friendly

Another alternative is the Electric Arc Furnace (EAF) which uses electricity to melt scrap metal and produce steel. This method is particularly effective for recycling old steel and reducing waste. While these modern techniques have largely replaced the Bessemer process they owe their existence to the innovations pioneered by Sir Henry Bessemer

The Economic Impact of the Bessemer Process Steel

The economic implications of the Bessemer process steel cannot be overstated. By making steel production more efficient and cost-effective the process spurred economic growth across the globe. Industries that once relied on expensive materials could now afford to use steel driving innovation and expansion

Consider the construction industry. Before the Bessemer process steel was too costly to use in large-scale projects. But with the introduction of affordable steel builders could construct larger more complex structures. This led to the development of modern cities with towering skyscrapers and sprawling infrastructure

Global Adoption of the Bessemer Process

The Bessemer process steel quickly gained popularity worldwide as countries realized its potential. Factories in Europe North America and Asia adopted the method transforming their industries and economies. The widespread adoption of the process contributed to the globalization of steel production making it a truly international industry

But the economic impact wasn't limited to steel production alone. The availability of cheap steel spurred innovation in other sectors as well. From transportation to manufacturing industries across the board benefited from the advancements made possible by the Bessemer process

Environmental Considerations and the Future of Steel Production

As the world becomes more environmentally conscious the future of steel production must address sustainability. While the Bessemer process steel was a groundbreaking innovation it also had a significant environmental footprint. Modern methods like the BOF and EAF have reduced this impact but there's still work to be done

One promising development is the use of green technologies in steel production. Innovations such as hydrogen-based reduction and carbon capture are being explored to make the process cleaner and more sustainable. These advancements build on the legacy of the Bessemer process while addressing the challenges of the modern world

Conclusion: The Legacy of the Bessemer Process Steel

In conclusion the Bessemer process steel remains one of the most significant innovations in industrial history. From its humble beginnings in the mid-19th century to its widespread adoption across the globe this method transformed how we produce and use steel. While modern alternatives have emerged the principles of efficiency and innovation pioneered by Sir Henry Bessemer continue to inspire

So the next time you walk through a city or ride a train take a moment to appreciate the role of the Bessemer process in shaping our world. And if you're interested in learning more about the future of steel production be sure to explore the latest advancements and technologies driving the industry forward. After all the story of steel is far from over – it's a story that continues to evolve with each new innovation

Call to Action: Share your thoughts on the impact of the Bessemer process steel in the comments below. And don't forget to check out our other articles on industrial history and innovation

Table of Contents

- What Exactly is the Bessemer Process Steel?

- The History Behind the Bessemer Process Steel

- The Science Behind the Bessemer Process Steel

- Challenges and Limitations of the Bessemer Process Steel

- The Economic Impact of the Bessemer Process Steel

- Environmental Considerations and the Future of Steel Production

- Advantages of the Bessemer Process

- Modern Alternatives to the Bessemer Process

- Global Adoption of the Bessemer Process

- Conclusion: The Legacy of the Bessemer Process Steel

:max_bytes(150000):strip_icc()/Bessemer-process01-3000-3x2gty-58b4e7c75f9b586046963aff.jpg)